- About -Company Profile-Organization-History-Culture-Design ability-Production capacity

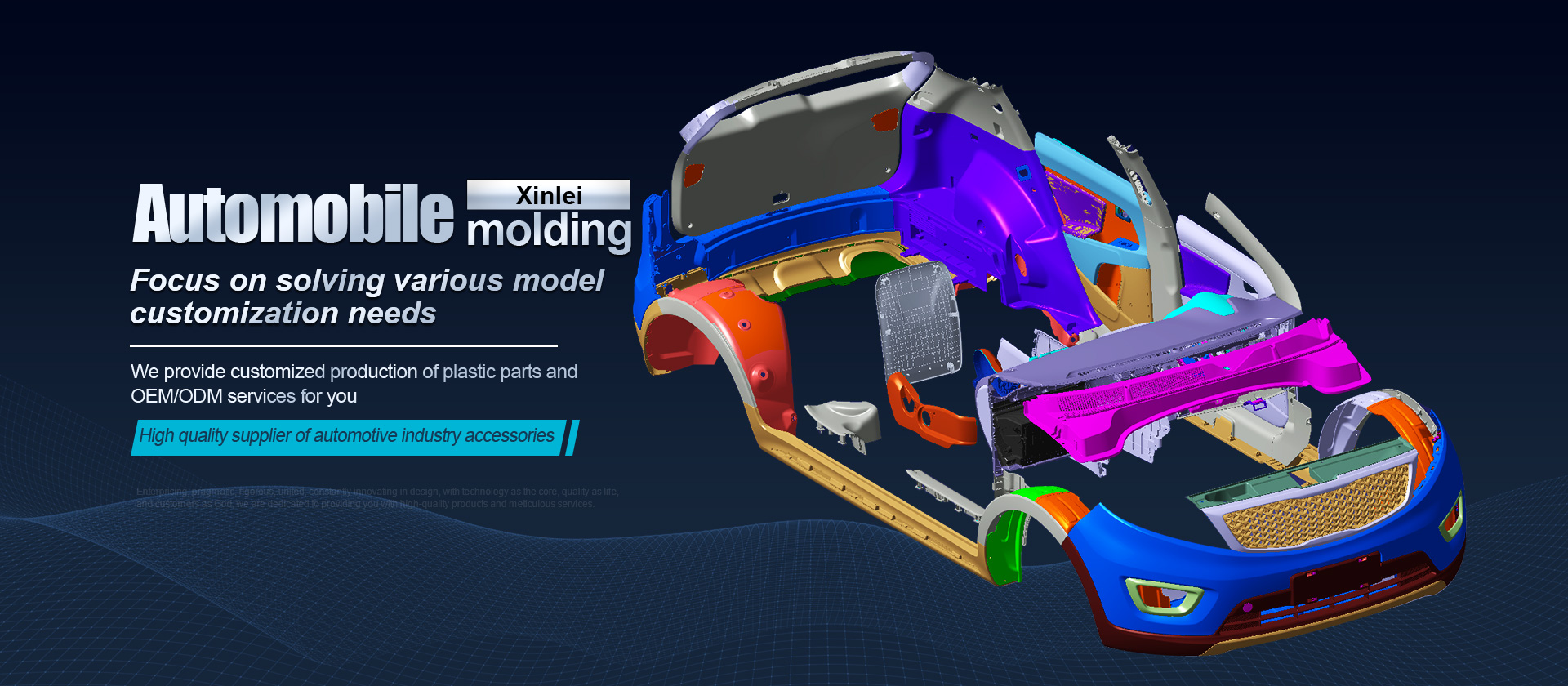

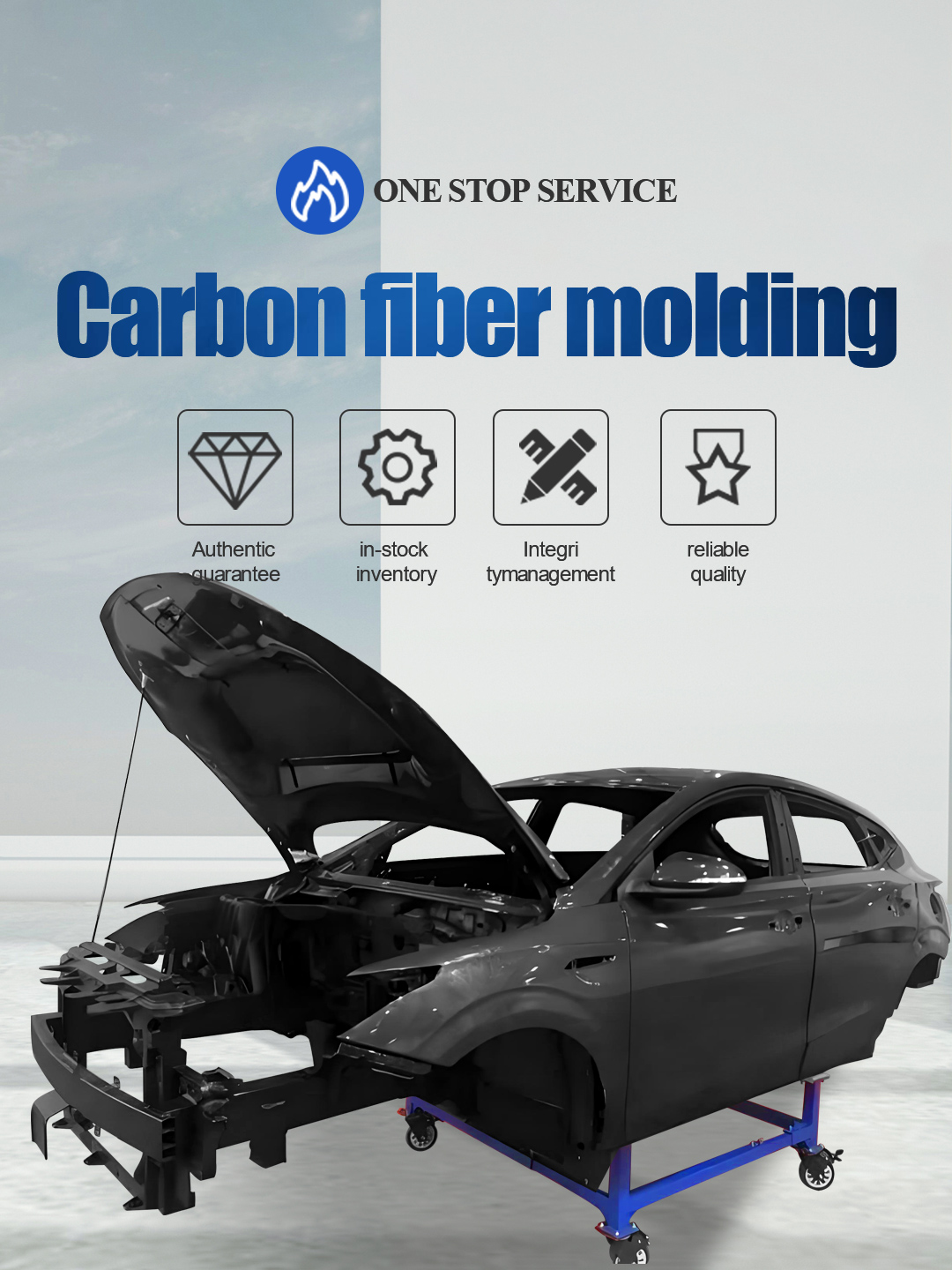

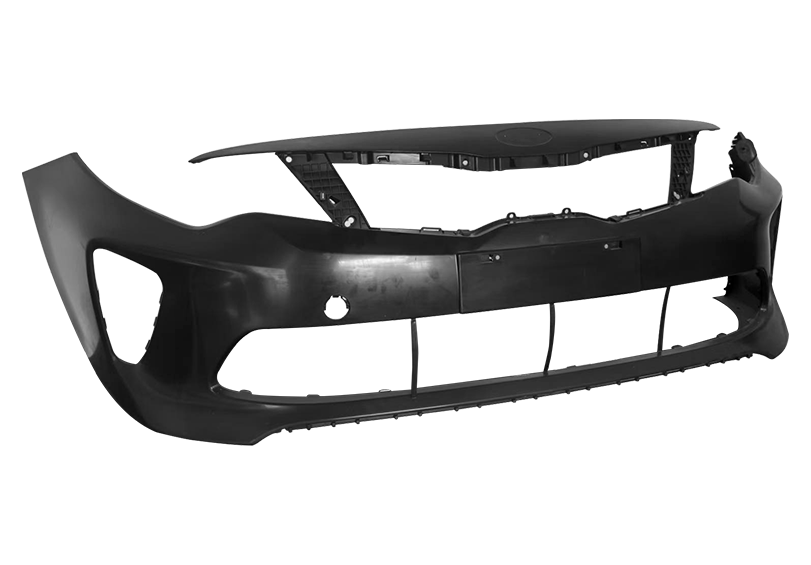

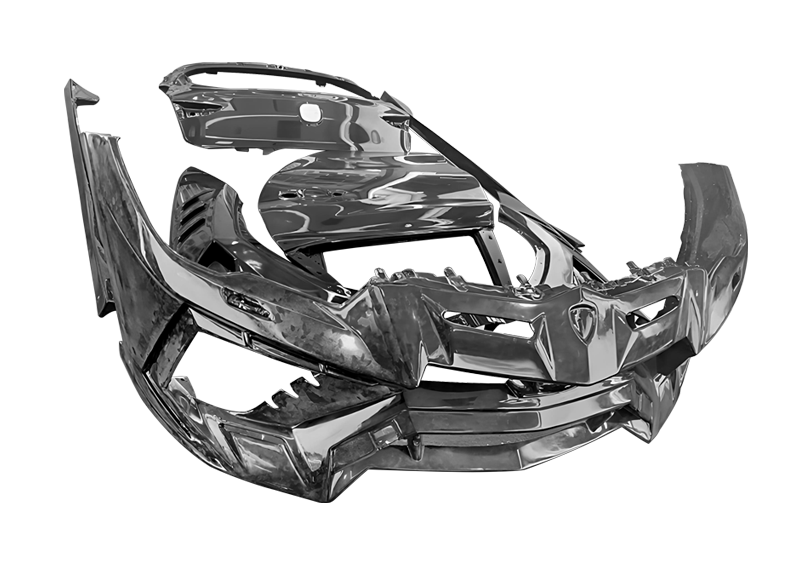

- Product -Automotive interior and exterior parts-Electrical appliances-Commodity-Carbon fibre

- News -Xinlei News-Industry News-FAQ

- Service -Main business-Partial application cases-Partnership-Anxin Service

- Contact -Contact-Recruitment-Join

Jiangsu Xinlei Mold&Plastic Co., Ltd

Phone: 0515-89806501

Fax: 0515-89806502

Contact: Manager Yang

Email: xlzl@xlpmould.com

Yancheng Address:

No. 6 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu Province

Zhejiang Address:

No. 12 Yangshan Road, Jianshan New District, Haining City, Jiaxing City, Zhejiang Province

No. 2 Jinniu Road, Xinqian Street, Huangyan District, Taizhou City, Zhejiang Province

- Copyright © 2025 Jiangsu Xinlei Mold&Plastic Co., Ltd Record number:Su ICP No. 10003027

- Website construction:Sike Network Keyword:Automotive interior and exterior parts Electrical appliances Commodity Carbon fibre